In today’s fast-paced manufacturing world, efficiency, precision, and innovation are paramount. One technology that is increasingly shaping industries like automotive, aerospace, and consumer goods is repmold.

But what exactly is repmold, and how does it fit into modern manufacturing? This article will dive into the meaning of repmold, its real-world applications, and why it’s becoming a game-changer in the industry.

Introduction to Repmold: The Basics

Repmold is a specialized term in the world of manufacturing, specifically referring to the process of rapid tooling and mold production using modern techniques such as additive manufacturing (3D printing) and subtractive manufacturing. It’s a term that has been gaining traction in recent years, particularly in industries where time, cost-efficiency, and precision are critical.

The beauty of repmold lies in its ability to deliver faster mold production with reduced costs, especially in low-volume manufacturing or prototyping stages. Whether you’re in the automotive sector testing new designs or working on prototypes for consumer goods, understanding repmold is key to staying ahead of the curve.

By the end of this article, you’ll have a clear understanding of what repmold is, how it works, and how it benefits industries like yours. We’ll also explore the various applications and how it contributes to shaping future manufacturing processes.

What is Repmold?

At its core, repmold refers to the process of creating molds using rapid prototyping methods. Traditional mold-making often involves extensive time and labor, with high upfront costs. Repmold, on the other hand, leverages innovative technologies to produce molds much faster and at a fraction of the cost, particularly beneficial during the early stages of product development or for short-run production.

It combines rapid prototyping with the manufacturing of physical molds, making it an ideal choice for businesses that need to get their products to market faster and more affordably. Using 3D printing or CNC machining, manufacturers can create accurate and high-quality molds that allow them to produce parts quickly.

How Does Repmold Work?

The repmold process typically involves two primary approaches: 3D printing (additive manufacturing) and subtractive manufacturing (CNC machining). Let’s take a look at both.

1. Additive Manufacturing (3D Printing)

In additive manufacturing, the mold is created layer by layer from a digital design file, typically made from materials like thermoplastics or resins. This technique allows for intricate designs and shapes that would be impossible or very expensive to achieve using traditional methods. The key advantage of this approach is speed. 3D-printed molds can be made in hours, rather than the days or weeks required by traditional methods.

2. Subtractive Manufacturing (CNC Machining)

CNC (Computer Numerical Control) machining is another technique used to create repmolds. In this case, a solid block of material (such as metal or plastic) is gradually cut and shaped into a mold using precision machinery. Although not as fast as 3D printing, CNC machining offers extremely high accuracy and can be used to produce molds that need to withstand higher temperatures or wear and tear.

3. Hybrid Approaches

Often, manufacturers will combine both methods for even greater efficiency and cost savings. For example, a mold might be 3D printed for its initial design, and then CNC-machined to refine specific areas or improve durability.

For More Learing About realistic Go To: PureArtSketch

Real-World Uses of Repmold

Repmold is not just an academic concept; it has real-world applications across several industries. Let’s explore how this innovative technology is making waves.

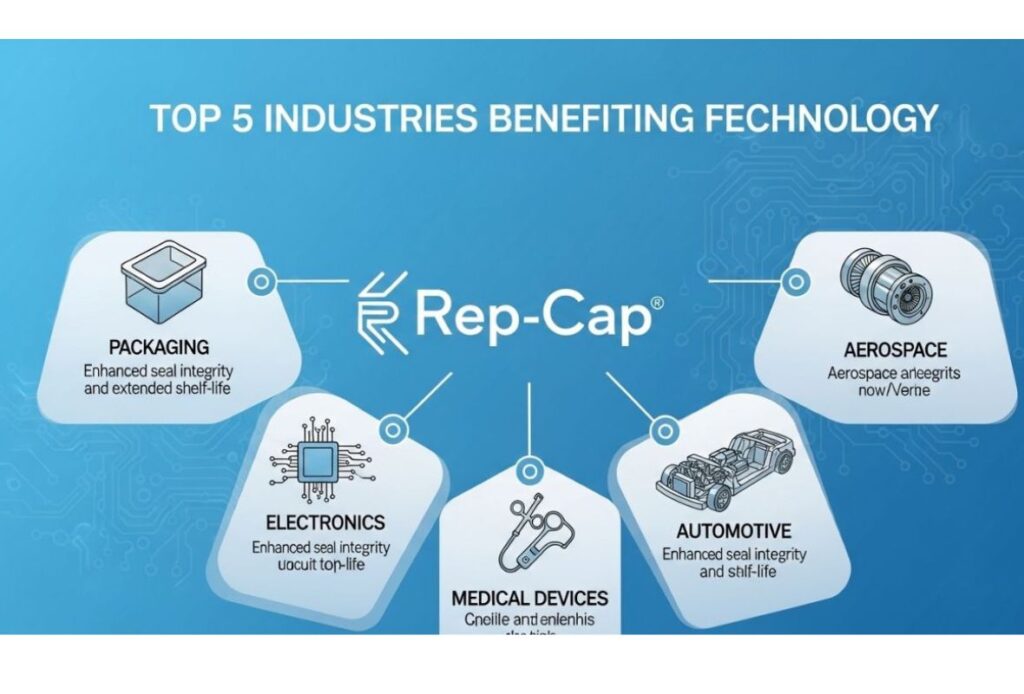

1. Automotive Industry

In the automotive sector, repmold is used to create prototype parts and small batch production runs. This is particularly useful when manufacturers need to test designs quickly, make adjustments, or create custom parts for low-volume vehicles.

The traditional method of making molds for automotive parts can be costly and time-consuming. Repmold allows manufacturers to cut down on mold production time, allowing for faster design iterations and quicker time-to-market for new vehicles or parts.

2. Aerospace and Defense

In aerospace and defense, precision is critical. The ability to create custom molds for specialized parts whether they are for an aircraft wing or a space shuttle component; is essential. Repmold’s precision and ability to create complex geometries make it a valuable tool in the aerospace industry, where components often require intricate designs that are difficult to produce using traditional molding methods.

3. Consumer Goods & Electronics

The consumer electronics industry, which thrives on innovation and speed to meet consumer demand, also benefits from repmold. From smartphone casings to wearable technology, repmold allows manufacturers to quickly create molds for testing new designs without incurring the high costs of traditional tooling. This is especially useful for companies that are constantly evolving their products and need flexibility in production.

4. Medical Devices

Medical device manufacturers need to ensure their products meet strict safety and regulatory standards. Repmold allows for rapid prototyping of medical components, such as surgical instruments or implants, helping manufacturers test designs before committing to large-scale production. This saves time and money while ensuring that the final product is functional and meets all required specifications.

Benefits of Repmold

The rise of repmold can be attributed to its numerous benefits. Here’s why industries are increasingly turning to this technology:

1. Cost Efficiency

Traditional molding methods are expensive due to the need for high-quality materials, extensive labor, and long production times. Repmold reduces these costs by speeding up the process and allowing for lower-cost materials to be used, especially in the early stages of product development.

2. Speed and Flexibility

Repmold enables manufacturers to quickly adapt to changes, whether it’s tweaking a product design or adjusting the size of a mold. The fast turnaround time means rapid iteration cycles, allowing for faster product development and the ability to meet market demands quickly.

3. Precision and Customization

Molds created through repmold methods are often more precise than those produced through traditional methods. The customizability of the process also allows manufacturers to create molds with complex geometries that would be impossible using conventional molding techniques.

For More Learing About realistic Go To: PureArtSketch

4. Reduced Waste

Traditional mold-making processes often result in a considerable amount of material waste. With repmold, especially in 3D printing, material is deposited only where needed, reducing waste and contributing to more sustainable manufacturing practices.

The Future of Repmold: What’s Next?

As manufacturing technology continues to evolve, the use of repmold will likely expand. With advancements in material science and machine learning, repmold processes will become even more efficient, enabling the creation of molds for even more specialized applications. As industries demand greater customization and faster turnarounds, the repmold process will likely become more prevalent in mainstream manufacturing.

Conclusion

Repmold has revolutionized the way industries approach mold production. With its ability to deliver cost-effective, fast, and highly precise molds, repmold is quickly becoming an indispensable tool in fields ranging from automotive to medical device manufacturing.

Whether you’re developing a new prototype or producing low-volume components, repmold offers an efficient, flexible, and affordable solution that helps companies stay competitive in an ever-evolving marketplace.

As technology continues to improve, the applications for repmold will expand, making it a cornerstone of modern manufacturing practices. If you’re looking to innovate in your field, embracing repmold could be your next big step.

Frequently Asked Questions

1. What is the difference between repmold and traditional mold-making?

Repmold uses advanced technologies like 3D printing and CNC machining to create molds faster and more affordably than traditional methods, which often require high upfront costs and lengthy production times.

2. Can repmold be used for large-scale production?

While repmold is ideal for low-volume production or prototyping, some processes can be scaled up for medium-volume production. However, traditional molding is typically preferred for large-scale manufacturing due to its efficiency at scale.

3. What materials are used in repmold?

Common materials include thermoplastics, resins, metals, and composites. The choice of material depends on the specific requirements of the mold and the final product.

4. How does repmold improve manufacturing timelines?

By reducing the time needed for mold production, repmold allows for quicker iterations and faster product development cycles, helping companies bring products to market more efficiently.

5. Is repmold more cost-effective than traditional methods?

Yes, repmold can significantly reduce mold production costs, particularly for prototypes or short-run manufacturing, by cutting down on labor, material waste, and tooling expenses.